📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

11/11 kV Paper Insulated Mining Cable – AS/NZS 1972 High Voltage Feeder

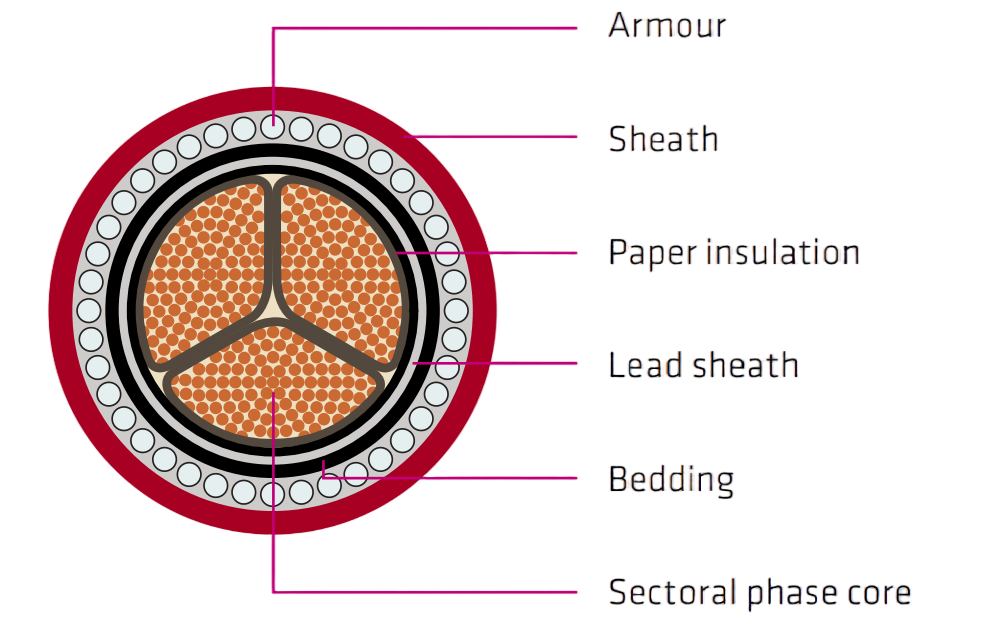

Lead Sheathed & Steel Wire Armoured Cable for Primary Mine Supply and Industrial Power Networks

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Cable Type | Paper Insulated, Paper Belted, Lead Sheathed, GSW Armoured Mining Cable |

Applicable Standards | AS1026, AS/NZS 1972 |

Rated Voltage | 11/11 kV |

Conductor Material | Compacted shaped plain annealed copper conductor |

Conductor Screen | Semiconductive tape screen |

Insulation | Impregnated paper tape (numbered cores), overall paper tape belt insulation |

Inner Sheath | Lead alloy |

Bedding | Bitumen impregnated paper and textile tape |

Armour | Galvanised steel wire (GSW) armour providing ≥50% conductor conductance |

Outer Sheath | Red PVC |

Maximum Operating Temperature | +65 °C |

Minimum Operating Temperature | 0 °C |

Flexibility | Rigid |

Chemical Resistance | Very good — suitable for frequent chemical exposure |

Mechanical Impact Resistance | Very heavy |

Water Resistance | Suitable for immersion and temporary water coverage |

UV and Weather Resistance | Suitable for direct solar radiation and outdoor exposure |

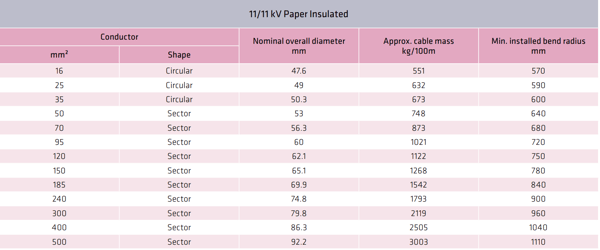

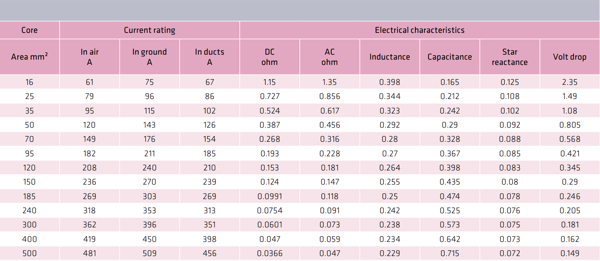

Physical & electrical characteristics

This 11/11 kV paper insulated, paper belted, lead sheathed, galvanised steel wire (GSW) armoured cable is designed according to AS1026 and AS/NZS 1972 standards. It is widely used as a high voltage feeder cable in power reticulation systems throughout mines and industrial networks. Suitable as a primary power supply cable for systems requiring high earth fault current capacity. Note that the 12.7/22 kV XLPE cable variant offers alternative advantages such as higher temperature rating allowing cable size reduction, with associated cost, size, and weight savings.

Product Features

High Voltage Capability: Designed for 11/11 kV power reticulation systems in mining and industrial environments.

Robust Construction: Paper insulated and belted cores with lead alloy inner sheath and galvanised steel wire armour provide mechanical strength and excellent electrical performance.

Durable Outer Layer: PVC outer sheath in red for environmental protection and identification.

High Earth Fault Capacity: Suitable for systems requiring high earth fault current capabilities.

Wide Installation Options: Suitable for installation in free air, ducts, or direct buried applications.

Traditional Design: While effective, the cable is rigid and has no fire performance rating compared to modern XLPE alternatives.

Application Areas

Used extensively across mining power reticulation networks as primary power supply cables, especially where high earth fault values are expected.

Quality Certifications

AS1026

AS/NZS 1972

Installation and Maintenance

Applicable for free air, duct, or buried direct installation. Cable’s rigid construction requires appropriate handling techniques. Regular inspections are recommended to maintain cable integrity.

Customization Services

Custom lengths and particular construction variations can be provided upon request.

Contact Us

For quotations, detailed datasheets, and customized mining cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat