📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

12.7/22 kV Copper XLPE Mining Cable – AS/NZS 1972 Armoured Feeder

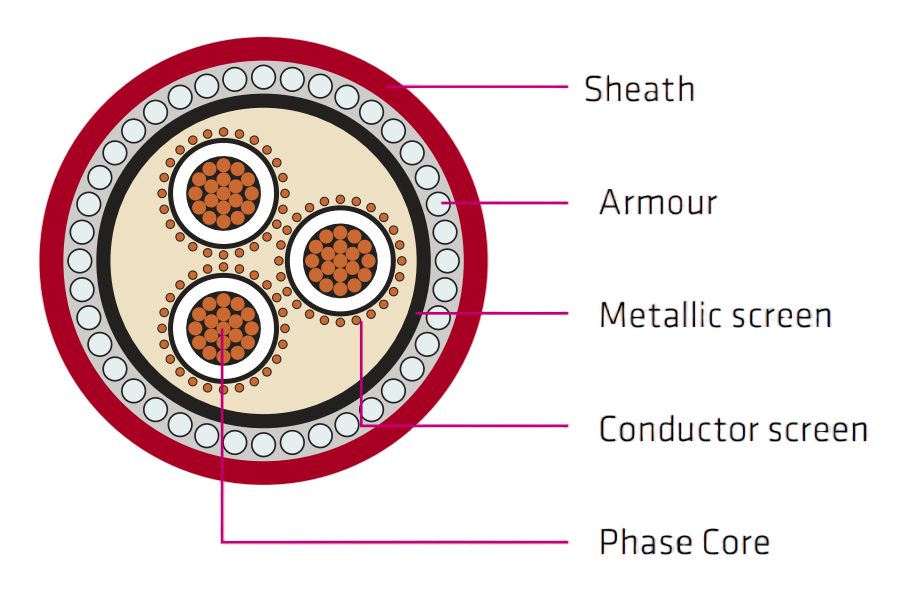

High Voltage 3-Core Copper Cable with XLPE Insulation and Steel Wire Armour for Primary Mine and Industrial Supply

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Cable Type | Three-core Copper Wire Screened Armoured Cable |

Applicable Standards | AS/NZS 1972 |

Rated Voltage | 12.7/22 kV |

Conductor Material | Plain circular compacted copper conductor |

Conductor Screen | Extruded semiconducting compound bonded to insulation |

Insulation | Cross Linked Polyethylene (XLPE) |

Insulation Screen | Extruded semiconducting compound |

Metallic Screen | Plain annealed copper wire providing not less than 50% conductance of one conductor |

Armour | Galvanised steel wire (GSW) |

Outer Sheath | Red 5V-90 Polyvinyl Chloride (PVC) |

Maximum Operating Temperature | +90 °C |

Minimum Operating Temperature | -25 °C |

Minimum Bending Radius | Installed cables: 12 × overall diameter (12D) |

Flexibility | Rigid |

Chemical Resistance | Very good — suitable for frequent chemical exposure |

Mechanical Impact Resistance | Very heavy |

Water Resistance | Resistant to water splashes |

UV and Weather Resistance | Very good — suitable for direct solar radiation and outdoor exposure |

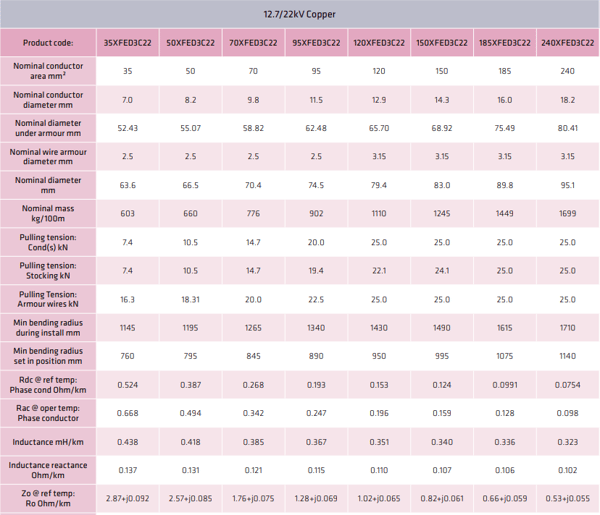

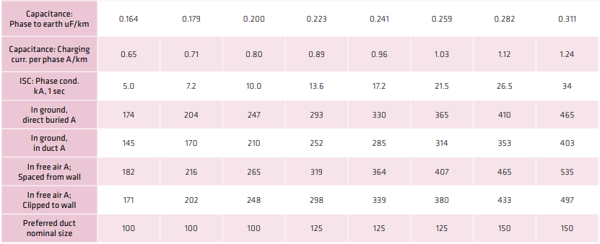

Physical & electrical characteristics

This 12.7/22 kV three-core copper wire screened armoured cable is designed to AS/NZS 1972 standards for heavy industrial and mining applications. With XLPE insulation and galvanised steel wire (GSW) armour combined with a PVC outer sheath, this cable is suitable as a primary power supply for mines and industrial networks. It offers excellent electrical performance, mechanical strength, and environmental resistance while complying with flame retardant requirements.

Product Features

Heavy-Duty Construction: XLPE insulation, semiconducting screens, galvanised steel wire armour, and robust PVC sheath for superior mechanical and environmental protection.

Flame Retardant: Compliant with AS/NZS 1972 flame retardant requirements, enhancing safety in mining and industrial environments.

High Electrical Performance: Copper conductors with semiconducting screens provide excellent conductivity and screening effectiveness.

Installation Versatility: Suitable for installation in free air, ducts, trenches, and direct ground burial.

Rigid Cable: Designed for stable, long-term use in fixed installations requiring robust mechanical strength.

Application Areas

Suitable as primary power supply cable in mines and industrial electrical reticulation networks, supporting heavy-duty electrical distribution systems.

. Quality Certifications

AS/NZS 1972

Installation and Maintenance

Suitable for installation in free air, ducts, ground, and trench conditions. Installation should observe the minimum bending radius (12D) and proper handling for rigid cables. Regular maintenance inspections are advised to ensure optimal cable performance.

Customization Services

Custom cable lengths and project-specific requirements can be accommodated upon request.

Contact Us

For quotes, detailed technical datasheets, and customized cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat