📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

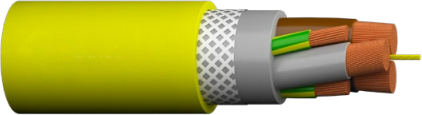

FEICHUN-M-PUR Braided Mining Reeling Cable – 1 kV

Reinforced with braiding for higher tensile strength and fast reeling operations

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Rated Voltage | U0/U (Um): 0.6/1 (1.2) kV |

Test Voltage | 2.5 kV |

AC Test Voltage (Control Cores) | 2 kV |

Nominal Voltage | 1,000 V |

Maximum Conductor Temperature | 90 °C |

Max Conductor Temperature at Short Circuit | 250 °C |

Ambient Temperature Fixed Installation | –40 °C to +80 °C |

Ambient Temperature Flexible Installation | –30 °C to +80 °C |

Conductor | Finely stranded bare copper, class 5 |

Insulation | XLPE |

Construction | Three main conductors (brown, black, grey) laid-up with split earth conductor in cable interstices; cores with very short lay length |

Carrier Element | Central Aramid yarn carrier |

Outer Sheath | Halogen-free polyurethane (PUR) with braided reinforcement |

Torsional Stress | ±50°/m |

Permanent Tensile Strength | 25 N/mm² |

Travel Speed | Underground reeling operation: up to 100 m/min |

Bending Radius | Fixed Installation: 4 × cable diameter; Reeling Operation: 8 × cable diameter |

FEICHUN-M-PUR BRAIDED is a flexible low voltage reeling cable featuring optimized dimensions and a flame retardant, halogen-free polyurethane (PUR) outer sheath. Designed primarily for power supply to underground mining and tunneling equipment, it is engineered for demanding dynamic loads such as reeling operations on drilling machines, scoops, and LHDs. The cable includes a central aramid carrier for enhanced mechanical strength and a braided sheath to withstand abrasion and mechanical stresses commonly encountered in trailing and reeling applications.

Standards and Certifications

DIN EN 60228 / IEC 60228 / VDE 0295

DIN VDE 0298-300

IEC 60502-1

DIN VDE 0298-4

DIN EN 60332-1-2 / IEC 60332-1-2

Chemical and Environmental Resistance

Halogen-free and flame retardant

Resistant to ozone and UV radiation

Suitable for application up to defined water exposure levels (max water depth unspecified)

Product Features

Optimized Flexibility and Dimension: Suitable for underground mining and tunneling equipment with frequent dynamic loading such as reeling.

Central Aramid Carrier: Provides excellent tensile strength and mechanical reinforcement.

Braided Sheath Protection: Enhances abrasion resistance and cable durability in trailing and reeling operations.

Halogen-Free Polyurethane Outer Sheath: Flame retardant and environmentally resistant.

High-Speed Reeling Capability: Designed to endure travel speeds of up to 100 m/min underground.

Wide Operating Temperature Range: Effective in harsh underground temperature conditions.

Application Areas

Ideal for power supply cables on underground mining machinery including drilling rigs, scoops, and LHDs subject to frequent mechanical stress and abrasion.

Installation and Maintenance

Can be installed in fixed and flexible configurations respecting minimum bending radius guidelines. Regular inspection is recommended to ensure durability in dynamic underground environments.

Customization Services

Available with varying conductor sizes and lengths, as well as tailored mechanical reinforcements, to meet specific operational requirements.

Contact Us

For quotations, detailed datasheets, and customized flexible mining cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat