📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

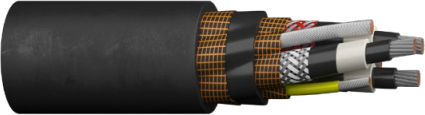

PROTOLON (SB) SHD-GC Flexible Trailing Cable – 5/15 kV

Shielded heavy-duty cable with copper core and ground-check for mining equipment

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Voltage Ratings | 5 kV, 8 kV, 15 kV |

Test Voltages | 14 kV (5 kV), 23 kV (8 kV), 43 kV (15 kV) |

Maximum Conductor Temperature | 90 °C |

Max Conductor Temperature at Short Circuit | 250 °C |

Ambient Temperature (Fixed) | -40 °C to +80 °C |

Ambient Temperature (Flexible) | -30 °C to +60 °C |

Conductor Material | Finely stranded tinned copper; Ground-check conductor: finely stranded tinned copper with yellow rubber insulation |

Insulation | Semi-conductive EPR |

Core Construction | Three main conductors with individual concentric mixed screen of tinned copper and colored polyester yarn, laid up with 2 ground conductors and one ground-check conductor located in outer interstices |

Reinforcement | Tear-resistant reinforcing tape over assembly |

Outer Sheath and Screening | EPR rubber PROTOLON insulation; Semi-conductive NBR easy strip; Polyester mesh tape; Polychloroprene (PCP) rubber sheath |

Mechanical Properties | Torsional stress: ±25°/m; Permanent tensile strength: 20 N/mm² (static) |

Bending Radius | 6 × diameter (fixed installation), 10 × diameter (flexible operation) |

PROTOLON (SB) SHD-GC is a shielded heavy-duty ground check cable designed for power supply or connection to large material handling machines such as excavators in open-cast mining. Engineered to withstand extremely high mechanical stresses including abrasion and chaffing during trailing operation, this cable provides excellent durability and performance. Its copper core shielding enhances electrical safety and reduces electromagnetic interference in demanding industrial mining environments.

Standards and Certifications

ANSI/NEMA WC 58

ICEA S-75-381

DIN VDE 0298-3

DIN EN 60332-1-2 / IEC 60332-1-2

IEC 60811-404

EN 50525-2-21

Chemical and Environmental Resistance

Flame retardant per EN/IEC 60332-1-2

Oil resistant

Ozone resistant

UV resistant

Product Features

Heavy-Duty Copper Core Shielding: Provides effective electrical shielding and enhanced safety for power distribution in harsh environments.

Engineered for Trailing Operation: Designed to withstand mechanical stresses, abrasion, and chaffing typical of trailing in mining operations.

Robust Construction: Includes concentric mixed copper and polyester yarn screening, tear-resistant tape, and durable PCP rubber outer sheath.

Wide Thermal and Mechanical Range: Supports operation in extreme temperature ranges and high torsional stress conditions.

Certified Quality: Complies with multiple international standards ensuring safety and performance.

Application Areas

Ideal for power feed and connection cables on large mobile material handling equipment such as excavators in open-cast mines, requiring robust trailing cables with electrical shielding.

Installation and Maintenance

Suitable for fixed and flexible installations with bending radius compliance per VDE 0298-3. Regular inspections in abrasive environments are recommended to maintain cable integrity.

Customization Services

Available with various conductor sizes, voltage ratings, mechanical reinforcements, and lengths tailored to project-specific requirements.

Contact Us

For quotations, detailed technical datasheets, and tailored medium voltage flexible trailing cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat