📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

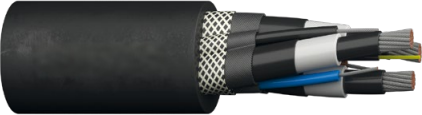

SAS (N)TSCGEWOEU 6/35kV Medium Voltage Mining Trailing Cable

UV, Oil & Flame-Resistant Cable for Mobile Mining Equipment

$10.00

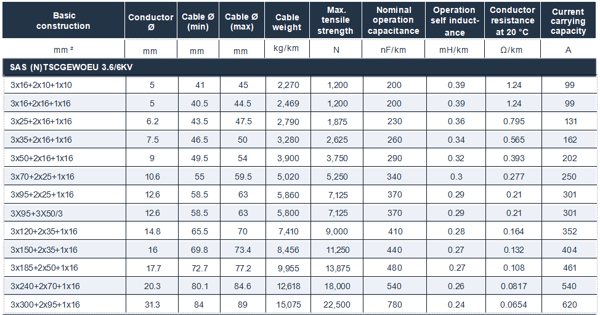

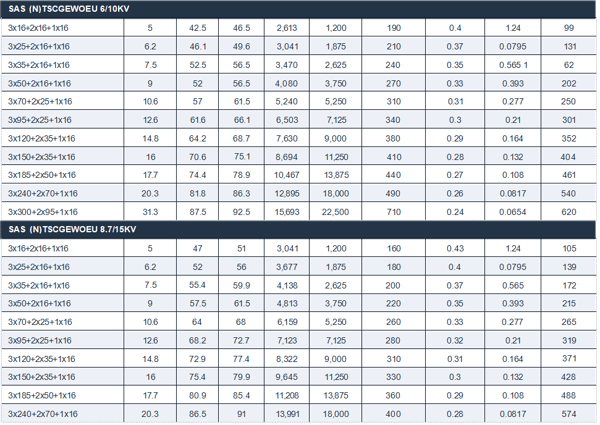

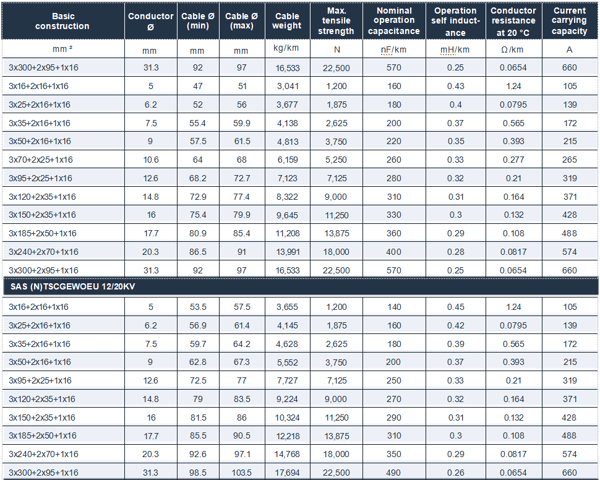

Technical Specifications

Parameter | Description |

|---|---|

Rated Voltage | 6/35 kV |

Maximum Conductor Temperature | 90 °C |

Short-Circuit Conductor Temperature | 250 °C |

Ambient Temperature (Fixed) | –50 °C to +80 °C |

Ambient Temperature (Flexible) | –50 °C to +60 °C |

Conductor | Finely stranded tinned copper, class 5; optional semi-conductive rubber-compound variant with tinned copper |

Conductor Screen | Semi-conductive EPR |

Core Configuration | Three cores laid up around a conductive central support element with aramid rope in the centre |

Insulation | EPR rubber (special compound 3GI3) |

Insulation Screen | Semi-conductive NBR easy-strip |

Inner Sheath | Copper tinned, class 5, EPR-insulated |

Outer Sheath | EPR rubber (special compound 5GM3) |

Mechanical Properties | Torsional stress ±100°/m; permanent tensile strength 20 N/mm² (static) |

SAS (N)TSCGEWOEU is a robust medium voltage trailing cable designed as a power supply to large mobile equipment in mining operations, including shovels and draglines. Its outer sheath remains fully flexible down to –50 °C and offers exceptional resistance to abrasion, tearing, and mechanical stresses encountered during trailing and reeling applications in harsh environments.

Product Features

Cold Flexibility to –50 °C: Outer sheath remains pliable in extreme low temperatures for reliable performance.

High Mechanical Durability: Engineered for abrasion, tearing, and torsional stresses in trailing and reeling operations.

Aramid-Reinforced Core Support: Central aramid rope enhances tensile strength and dimensional stability.

Comprehensive Environmental Resistance: EPR compounds ensure flame retardance, oil, ozone, and UV protection.

Wide Thermal Range: Suitable for fixed and flexible installations across –50 °C to +80 °C ambient conditions.

Application Areas

Designed for trailing and reeling power supply to heavy mobile mining machinery—shovels, draglines—in open-cast and underground operations where extreme cold flexibility and mechanical resilience are required.

Installation and Maintenance

Install respecting bending radius guidelines per VDE 0298-3. Suitable for fixed, flexible, and reeling applications. Routine inspections are advised to maintain sheath integrity and conductor performance under dynamic use.

Customization Services

Available with optional semi-conductive rubber-compound conductors, varied core counts, and tailored lengths to meet project-specific requirements.

Contact Us

For quotations, detailed technical datasheets, and customized cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat