📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

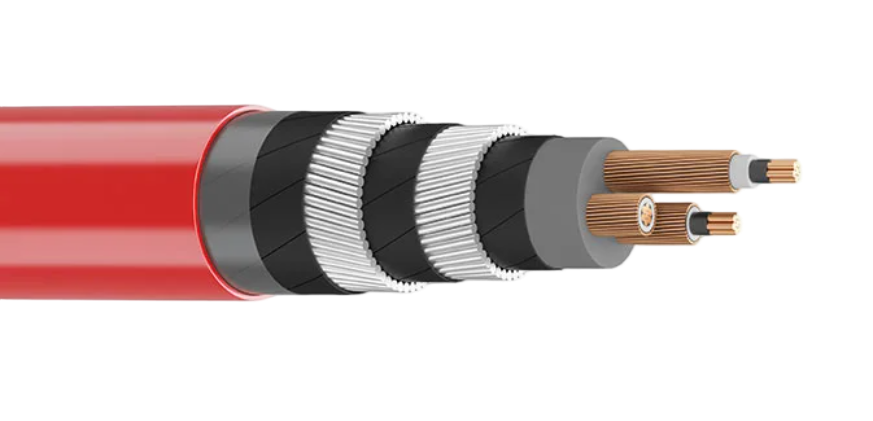

Single Point Suspension Cable – AS/NZS 1972 Borehole Mining Cable, 6.35/11kV to 22kV

Self-Supporting Borehole Cable with Double Armour, Torsion-Resistant Design for Coal & Metalliferous Mines

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Cable Type | Single Point Suspension (Borehole) Cable |

Applicable Standards | AS/NZS 1972 (Underground Coal Mines), AS/NZS 1429.1 (Metalliferous Mines) |

Rated Voltage | Typical voltages: 6.35/11 kV and 12.7/22 kV |

Conductor Material | Plain circular compacted copper |

Conductor Screen | Extruded semiconducting compound, bonded to insulation |

Insulation | Cross Linked Polyethylene (XLPE) standard |

Insulation Screen | Extruded semiconducting compound |

Metallic Screen | Plain annealed copper wire providing ≥ 50% conductance of one associated power conductor |

Armour | Galvanised steel wires (double armour for suspended length) |

Outer Sheath | Red 5V-90 Polyvinyl Chloride (PVC) |

Maximum Operating Temperature | +90 °C |

Physical & electrical characteristics

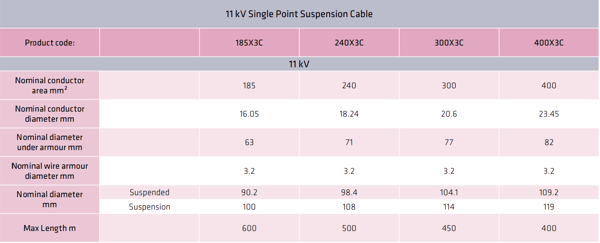

11 kV Single Point Suspension Cable

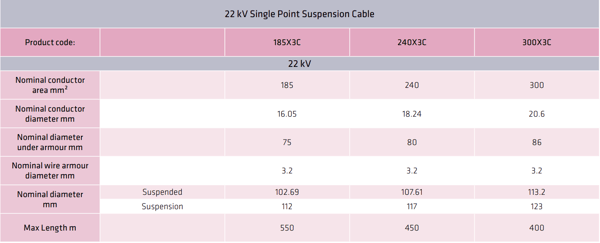

22 kV Single Point Suspension Cable

Single Point Suspension cables, also known as Borehole cables, play a vital role in both underground coal and metalliferous mining operations. Designed to be self-supporting when lowered vertically down shafts or boreholes, these cables transfer the mechanical strain from the suspension components — not the electrical conductors — ensuring durability and reliability. Featuring double armour construction engineered to resist torsional forces, SPS cables can be customized to include earth cores and fibre optic cables as required. Commonly applied in extensive overhead networks across mining sites, they provide power supply to remote working areas with typical voltages of 6.35/11 kV and 12.7/22 kV, conforming to AS/NZS 1972 and AS/NZS 1429.1 standards.

Product Features

Self-Supporting Design: Engineered to bear mechanical suspension strain through built-in components, protecting electrical conductors.

Double Armour Construction: Provides high resistance to torsional forces during suspension in vertical shafts or boreholes.

Versatile Core Options: Can incorporate earth cores and fibre optic cables as per project requirements.

Compliance and Safety: Meets Australian standards for underground coal and metalliferous mining environments (AS/NZS 1972 and AS/NZS 1429.1).

Durable Materials: XLPE insulation, semiconducting screens, and galvanised steel armour ensure high mechanical, chemical, and environmental resistance.

Application Areas

Primarily used in underground coal and metalliferous mines as suspension cables for overhead power networks, providing power to remote working areas via boreholes drilled at strategic points in the mine.

Quality Certifications

AS/NZS 1972

AS/NZS 1429.1

Installation and Maintenance

Designed to be suspended vertically from surface installations down mine shafts or boreholes. Proper installation ensures mechanical strain is absorbed by the cable armour and suspension system. Periodic checks recommended to maintain cable integrity and ensure optimal performance.

Customization Services

Options available to include earth cores, fibre optic cables, and tailored cable lengths according to specific project needs.

Contact Us

For quotations, detailed technical datasheets, and customized single point suspension cable solutions, please contact our sales or technical support teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat