📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

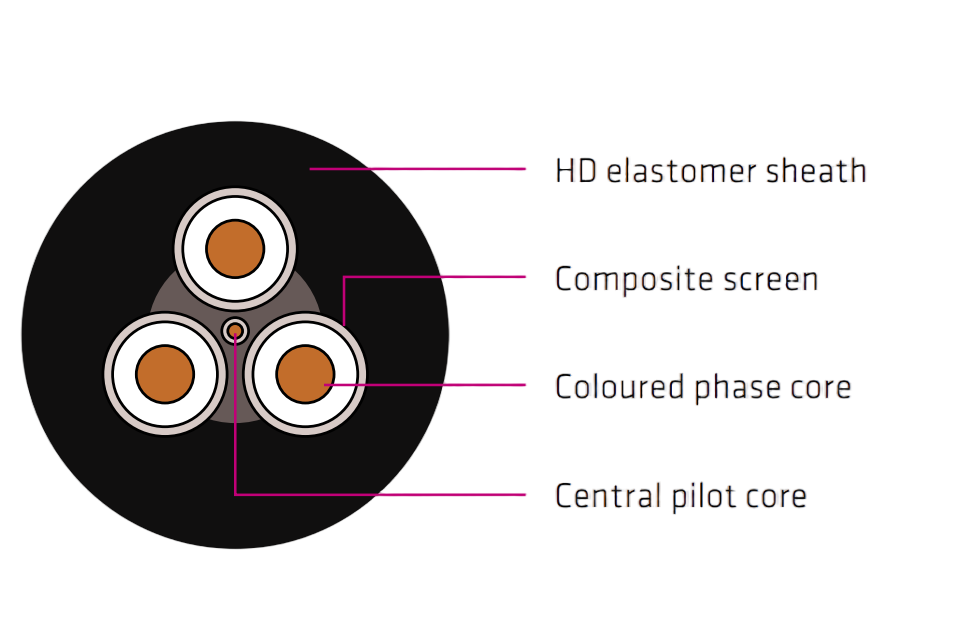

Type 409 Mining Cable – AS/NZS 2802 Heavy-Duty Trailing & Reeling Cable, 1.1kV–11kV

Metal-Screened Power Cores with Single Extensible Pilot, Kevlar® Reinforced Sheath for High Resistance to Abrasion, Weathering & Tear – Ideal for Pumps, Shovels, Draglines & Blast Hole Drills

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Cable Type | Class 2 Composite Screened Trailing Cable |

Applicable Standards | AS/NZS 2802 |

Rated Voltage | 1.1/1.1 kV to 11/11 kV |

Conductor Material | Tinned copper (three cores plus central pilot) |

Insulation | Class 2 EPR (R-EP-90) |

Insulation Tape | Textile for 1.1/1.1 kV; Semiconductive screen for ≥3.3 kV |

Screen | Composite screen of tinned annealed copper wire and polyester yarn (metal-screened) |

Core Colours | Red, White, Blue |

Pilot Conductors | Single extensible pilot conductor in cable centre |

Maximum DC Resistance | 3 Ω/100 m up to 35 mm²; 2 Ω/100 m above 35 mm² |

Sheath | Heavy duty HD-85-PCP with optional Kevlar® polyaramid yarn braid reinforcement |

Maximum Operating Temperature | +90 °C |

Minimum Operating Temperature | -25 °C |

Flexibility | Flexible |

Resistance to Chemical Exposure | Very good — frequent exposure |

Mechanical Impact Resistance | Heavy duty |

Water Resistance | Suitable for immersion and temporary water coverage |

UV and Weather Resistance | Very good — suitable for direct outdoor exposure |

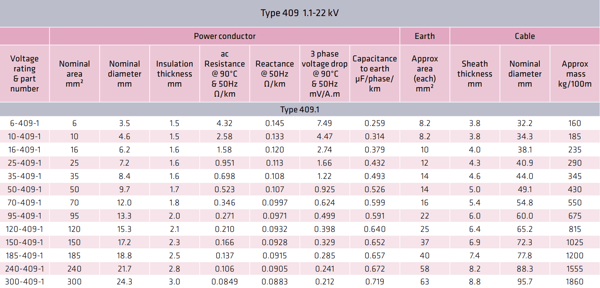

Type 409.1

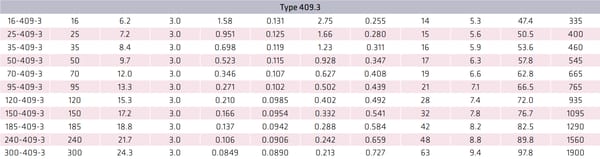

Type 409.3

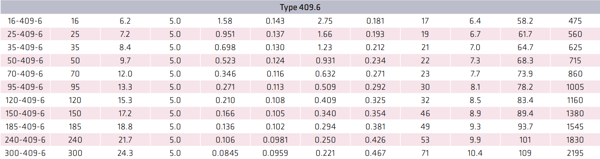

Type 409.6

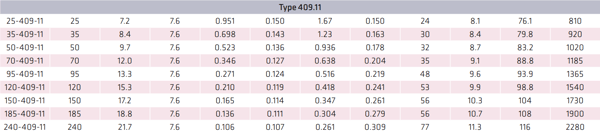

Type 409.11

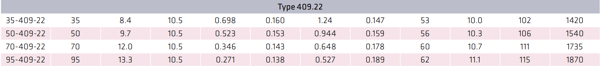

Type 409.22

Product Overview

Type 409 is a metal-screened power core cable with a single extensible pilot, designed for trailing and most reeling applications in the mining industry. Constructed to AS/NZS 2802 standards, this heavy-duty cable offers excellent flexibility along with high resistance to abrasion and weathering. It is suitable for demanding applications including pumps, shovels, draglines, and blasthole drills. For enhanced durability, cables (except Type 409.1 below 50 mm²) feature a Kevlar® polyaramid yarn braid sheath reinforcement, providing superior tear and cut-through resistance to withstand harsh mining conditions.

. Product Features

Heavy-Duty Construction: Designed for trailing and reeling applications with superior resistance to abrasion, weathering, and mechanical impact.

Kevlar® Reinforcement: Incorporates a high-strength polyaramid yarn (Kevlar®) braid sheath reinforcement (except Type 409.1 below 50 mm²), offering exceptional tear and cut-through resistance.

Composite Screened Power Cores: Metal screened cores for enhanced electrical performance combined with a single extensible pilot conductor for system control.

Fire Retardant: Meets all relevant flame and fire retardant requirements under AS/NZS 2802.

Flexible: Suitable for mobile equipment and free air installations, balancing durability with ease of installation.

Application Areas

Ideal for heavy-duty trailing cable applications in mining environments, including power supply to pumps, shovels, draglines, and blasthole drills where flexibility and durability against harsh conditions are required.

Installation and Maintenance

Suitable for installation in free air and on mobile mining equipment. Follow AS/NZS installation guidelines. Regular maintenance and inspection are recommended to preserve sheath integrity and performance.

Customization Services

Kevlar® braid reinforcement is optional and available based on project requirements. Custom lengths and specifications can be supplied on request.

Contact Us

For quotations, detailed technical datasheets, and customized solutions tailored to your mining project needs, please contact our sales or technical support teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat