📞+86 153 7530 2641 📧 hongjing.Wang@feichuncables.com

Type 441 Mining Cable – AS/NZS 2802 Class 1 Trailing & Reeling Cable, 1.1kV

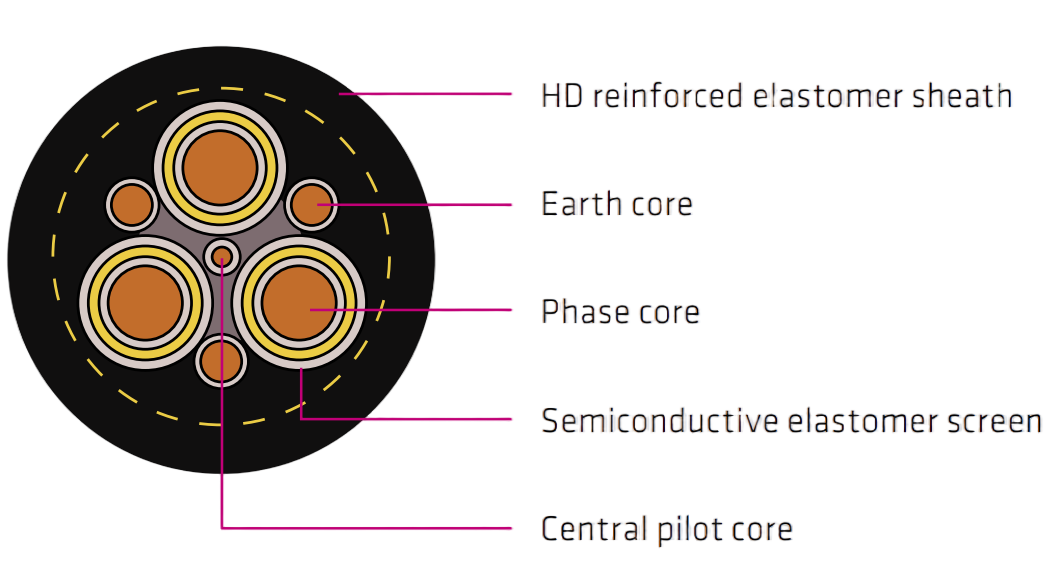

Semi-Conductive Screened Power Cores with Three Earth Cores & One Pilot Core – Compact Design, Kevlar® Reinforced, Flexible & Abrasion Resistant

$10.00

Technical Specifications

Parameter | Description |

|---|---|

Cable Type | Class 1 Semiconductive Screened Mining Cable |

Applicable Standards | AS/NZS 2802 |

Rated Voltage | 1.1/1.1 kV |

Conductor Material | Tinned copper (three cores plus three earth cores) |

Insulation | EPR (R-EP-90) with core identification by printed numbers on black semiconductive elastomer insulation screen |

Earth Conductors | Three semiconductive elastomer covered earth cores located in cable interstices |

Pilot Conductors | One EPR-covered tinned annealed copper extensible central pilot conductor |

Sheath | Heavy duty HD-85-PCP with optional Kevlar® polyaramid yarn braid reinforcement |

Maximum Operating Temperature | +90 °C |

Minimum Operating Temperature | -25 °C |

Flexibility | Flexible |

Chemical Resistance | Very good — suitable for frequent chemical exposure |

Mechanical Impact Resistance | Heavy duty |

Water Resistance | Suitable for immersion and temporary water coverage |

UV and Weather Resistance | Suitable for direct solar radiation and outdoor exposure |

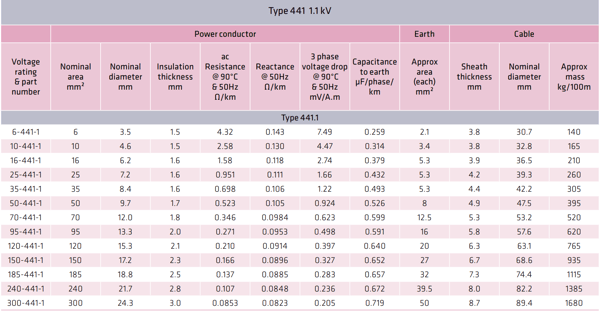

Physical & electrical characteristics

Type 441 1.1 kV is a semiconductive screened cable designed to AS/NZS 2802 standards, intended for general-purpose mining applications. Featuring semi conductive screened power cores with three earth cores and a single pilot conductor, this cable is suitable for slow reeling and trailing applications. As a Class 1 cable, it has lower insulation and sheath radials than Class 2, making it ideal for materials handling equipment or situations that require a smaller overall diameter and lighter mass. For enhanced durability, Type 441 cables incorporate a Kevlar® polyaramid yarn braid sheath reinforcement providing exceptional tear and cut-through resistance.

Product Features

Designed for Slow Reeling and Trailing Applications: Optimized for general materials handling and mining equipment requiring a compact, lighter cable.

Class 1 Cable Construction: Lower insulation and sheath radials allow reduced diameter and mass without compromising performance.

Kevlar® Reinforced Sheath: Polyaramid yarn braid reinforcement (optional) provides high tear and cut-through resistance.

Semiconductive Screen: Ensures electrical stability with screened power cores, earths, and a pilot conductor.

Fire Retardant: Meets AS/NZS 2802 flame and fire retardant standards.

Flexible and Durable: Suitable for installation on mobile equipment and in free air environments.

Application Areas

Ideal for trailing cables and slow reeling equipment in mining applications, especially materials handling tasks requiring space-efficient and lighter cables.

Installation and Maintenance

Suitable for installation in free air and on mobile mining equipment. Follow AS/NZS recommended practices with routine inspections to maintain cable integrity.

Customization Services

Kevlar® braid reinforcement and custom cable lengths available upon request to meet specific project needs.

Contact Us

For quotations, detailed technical datasheets, and custom mining cable solutions, please contact our sales or technical teams.

How to Reach Us

Get in Touch

SiteMap

Product Catalogue

Reeling Cable

Festoon Cable

Shore Power Cable

Scan to add us on WeChat